Livewell Capsules manufactures empty hard gelatine capsules in a continuous 24-hour process using high quality machines and equipment. Our best-in-class setup ensures that the capsules produced match all standard parameters defined by the industry internationally so that your filling operation is as smooth as possible. Our camera inspection machines ensure that any defective capsules are removed before the final packaging stage and printing machines are in place to print the logo or name you require on your capsules.

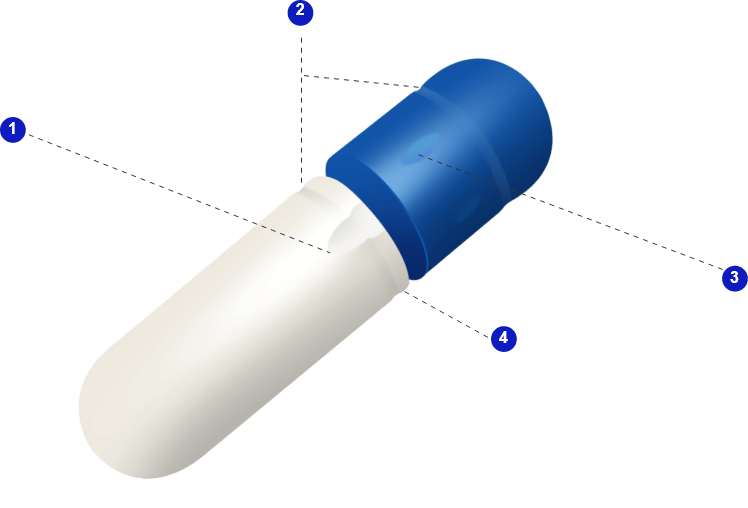

- Two air vents allow air to escape from the cap, essential during high speed filling

- Corresponding lock rings in body and cap provide a tight leak-free lock

- Six dimples to maintain the round shape of the capsule

- Tapered rim of the body ensures that the cap slides smoothly over the body

COLOURS

Options for colours of your capsules from Livewell are almost limitless. Any colour in opaque or transparent form can be developed by our colour specialists.

- Completely opaque capsules

- Transparent Colour Body with Opaque Colour Cap

- Clear Transparent Body with Opaque Cap

- Clear Transparent Capsules

Completely opaque capsules

Shield your contents with this versatile option

Transparent Colour Body with Opaque Colour Cap

A niche option used by some customers in which contents can be seen through the coloured body

Clear Transparent Body with Opaque Cap

Contents can be seen in this partially coloured option

Clear Transparent Capsules

The natural option used mostly for herbal ingredients

SPECIFICATIONS

The international capsule industry has established the set of standardised specifications used by capsule manufacturers and filling machines manufacturers. The best-in-class equipment used by Livewell produces capsules which comply to these parameters.